January 13, 2020

Posted by: Swenson Shear

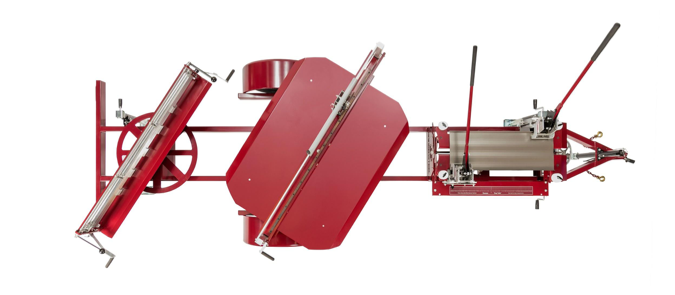

Standing Seam Roofs Are a Breeze With the Towable SnapTable PRO®

We all know that preparing and installing standing seam roof panels by hand can be a slow and arduous process. What if you could speed up the process while also improving the quality and consistency of your panels? It’s possible with Swenson Shear’s SnapTable PRO. Let’s take a look at five ways that this innovative tool is changing the game for standing seam roofers.

1. It’s An All-In-One Panel Preparation Tool for Standing Seam Roofs.

The SnapTable PRO is equipped with everything you need to quickly prepare high-quality metal panels for a standing seam metal roofing system, including a standing seam notcher, a panel cutter, and an eave and valley hemmer. It can prepare panels ranging in size from 12-24 inches, with cutting and hemming capabilities of up to 60 inches. The versatile nature of the tools means you can use it with all types of standing seam metal roof panels, including Cor-Ten, Nail Strip, Mechanical Seam, Zip-Rib, Snap Lock panels, and more. Plus, in addition to straight cuts, the SnapTable PRO can also accommodate angle cuts on metal panels for gables, hips, and valleys on a roof system.

2. It Speeds Up The Metal Roofing Panel Preparation Process.

The traditional method for preparing standing seam metal roofing panels involves hiring a skilled team that works together to notch, cut, and hem all the panels by hand. Even with an incredibly speedy, efficient team, the manual nature of preparing panels a roofing system requires a significant time investment. The SnapTable PRO, on the other hand, can prepare a full metal roofing panel in mere seconds.

3. It Only Requires A Single Person To Prepare a Standing Seam Panel.

Reliable, skilled labor isn’t cheap, nor is it always simple to find. The SnapTable PRO is designed to be operated by a single person with minimal physical effort required. It’s also super user-friendly — virtually anyone can operate it! This eliminates the need to hire multiple skilled workers to carry out metal roofing panel preparation. On average, the SnapTable PRO saves standing seam roofing companies 35-40% on labor costs.

4. It Yields Consistent, Factory-Like Cuts For Standing Seam Panels.

Cutting, notching, and hemming standing seam panels by hand can result in inconsistencies and imperfections, but with a SnapTable PRO, you can feel confident knowing that you’re producing precise, factory-quality metal roofing panels with little effort and in significantly less time.

5. It’s Lightweight And Transportable to Any Standing Seam Jobsite.

Transporting your SnapTable PRO to job sites is easy with Swenson Shear’s custom, hyper-light towable trailers. Instead of preparing your panels off-site and then transporting them to a job site, a towable SnapTable PRO allows you to streamline the process by preparing your standing seam panels directly on-site. Plus, no electricity is required to operate the SnapTable PRO, so it can be set up anywhere without worrying about a power source.

Standing Seam Roofers Choose Swenson Shear Metal Roofing Tools

Founded in 1959 and based in Ceres, CA, Swenson Shear is the #1 international provider of metal roofing tools for preparing roofing materials for standing seam metal roof installation, exposed fastener roofs, and stone coat shingle roofs. To request a quote for a towable SnapTable PRO or other standing seam metal roofing tools, contact [email protected] or call (877) 588-8748.